Success Stories

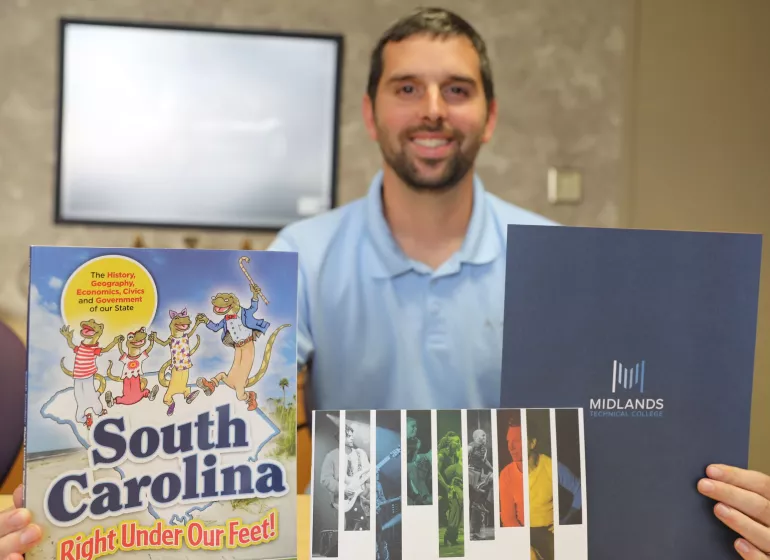

Doug Burch

“I’ve been telling people you’ve got to go this route. Go to MTC,” he said. Go there in the winter, go there in the fall. Go there in the spring, whenever you have the time. It’s exactly what I wanted.”

With unforeseen circumstances amid a pandemic, Doug Burch could have given up on his goals. Instead, he persevered and graduated with his Computer Numerical Control (CNC) certificate.

Burch was able to leave his job in the restaurant industry and accept a new position providing CNC work for Palmetto State Armory.

The Spring 2020 Computer Numerical Control (CNC) class found themselves facing unforeseen circumstances amid a pandemic but refused to let that stop them.

“We’ve had many successful groups throughout the years,” said Jeff Sigley, an MTC Manufacturing Faculty member. “This last group really had to lean in hard considering the pandemic’s impact on class schedules and delivery methods. Fortunately, I and the rest of our faculty, were always ready to go the extra mile for the students who were willing to tag along!”

One of the recent graduates, Doug Burch, was more than willing. Since completing the class, Burch was able to leave his job in the restaurant industry and accept a new position providing CNC work for Palmetto State Armory.

“I started off in the restaurant industry. I did very well, and it was great if that’s the career you want,” said Burch. “But, I had different goals in mind. I wanted a family, to have a better schedule, to make some good money, and to be proud of what I’m doing.”

Burch began to explore his options and looked into certifications that would get him directly into a new job field in a short amount of time.

“I wasn’t looking to do a year, two years, or four years. I was looking for a change now,” he explained. “The class was only six months, and it launched me into a new career with good pay.”

When his training began, Burch came into class with the idea that he wouldn’t have much competition. That thought quickly changed when he realized how different each student’s background was, and the motivations that drove them.

“There are people whose companies are paying for them to come learn, people who are fresh out of high school looking to make something of themselves, you’ve got a person who’s already an entrepreneur, and then me who’s got to change my career,” he said. “It suited everyone.”

Along with his new-found friendly competition, Burch found that the instructors at MTC would far surpass his expectations both inside and outside the classroom.

“I couldn’t have asked for a better instructor (Jeff Sigley), truly. As soon as I got into my new job, I started making suggestions, and they were like ‘hold on, we’ve never heard anybody say these types of things before,” said Burch. “He went above and beyond. He instructed us in a way that was very caring.”

When the college had to suddenly close campuses because of COVID-19, many students in the more hands-on programs were concerned that their training would be overlooked in the transition to virtual learning. For Burch, this was one of his biggest concerns as he felt that he would be ineffective in his future career without that hands-on training.

However, MTC was able to provide him with the resources he needed and experiences that made him less nervous around the tools and equipment.

“It gave me everything I need to know and more,” he explained. “We learned things that people don’t just go out and learn by doing their job. It not only sets you up to get yourself a position, but to get a higher position than you would have without any type of further certification.”

For anyone on the fence or considering attending Midlands Technical College for higher education or training, Burch had a few words of advice,

“I’ve been telling people you’ve got to go this route. Go to MTC,” he said. “Go there in the winter, go there in the fall. Go there in the spring, whenever you have the time. It’s exactly what I wanted. I set goals, I wrote them down, talked about them all the time, and then I achieved them.”

About Manufacturing and Skilled Trade Training in South Carolina

Midlands Tech offers trade training for many different facets of manufacturing. Find full training programs, certificates, or single courses to get the skills you need for these well-paying jobs. See all programs or browse categories below:

Automotive Technology

Automotive professionals work in shops and garages and are skilled in the building and repairing of engines.

Commercial Driver's License

Commercial truck drivers transport goods and materials locally and across the country. A CDL (Class A Commercial Driver’s License) is required for many jobs in this field.

Commercial Graphics

Commercial graphics technicians work in highly technical industries, designing and producing various types of printed materials.

Construction

Construction managers plan, financially monitor, and supervise projects and personnel on various construction sites.

Electrical and Electronics

Individuals in the electrical field test, troubleshoot, install, and repair electrical components. Electricians specialize in either residential or commercial electricity.

Forklift Operator

Forklift operators drive industrial trucks that transport materials in warehouses and on job sites. Forklift operators can be trained in as little as one day.

HVAC/R

Heating and air conditioning systems, as well as refrigeration and ventilation systems need HVAC mechanics and installers to repair and install air quality devices for homes and buildings.

Industrial Mechanical Maintenance

From troubleshooting to preventative maintenance, an industrial maintenance technician installs, repairs, and maintains industrial and commercial machinery in a variety of settings.

Mechatronics

Advanced automated manufacturing requires skilled maintenance and repair professionals. This program focuses on the engineering of electrical, mechanical, and computer systems to solve technical problems and maintain automated equipment.

Plumbing

Plumbers install, troubleshoot, and repair water, wastewater, and gas piping and fixtures in residential and commercial settings.

Precision Machining

Machined parts have to be made – and a CNC operator works to program, set up, and operate computer numerical control machines while also maintaining the highest standards of quality and safety.

Production

Those that work in production transform raw materials using labor, machines, and tools into products for use or sale. Such goods may be sold to other manufacturers for the production of more complex products.

Welding

Welding is used in the shipping, automotive manufacturing and repair, and aerospace industries. Welders join metal parts through melting and fusing them into a permanent bond.